A group of researchers from ETH Zurich, Switzerland, has introduced a new method of electronic waste management, which opens the door to a new job opportunity and a sustainable way to recover precious metals. The experts suggest that the electronic products we use at home may not only have components that can be recycled, but that gold present in motherboards, chips, or small circuits can also be extracted from them.

This approach, therefore, presents the possibility of recovering precious metals through the creation of jobs in the technology recycling sector. The recovery of gold is carried out through chemical processes that require specialized personnel, which creates a type of job opportunity to consider for those seeking employment or undergoing career transitions. This practice would offer advantages such as reduced dependence on traditional mining, lower pollution, and greater reuse of materials, among others.

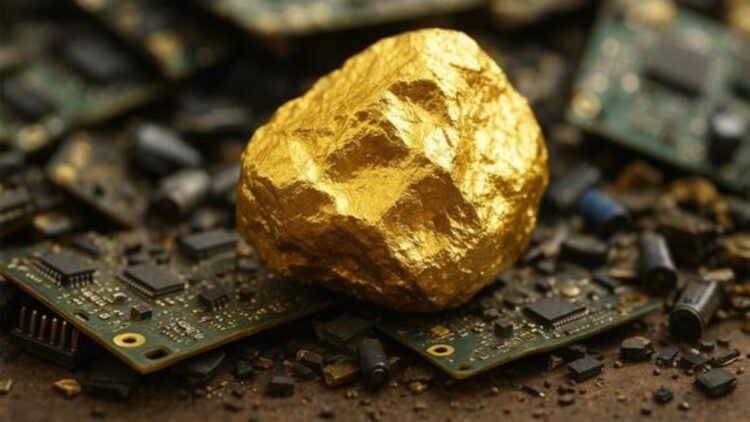

Gold recovery from electronic devices

A group of researchers from ETH Zurich (Switzerland) has discovered a method through which 22-karat gold can be extracted from electronic devices. According to the research, those electronic products that weigh only 25 g have components that can be recycled. In addition to that, they contain gold that can be extracted from motherboards, chips, or small circuits that we often overlook when disposing of our devices. This new approach presents advantages such as the opening of a specialized field of work in the collection, processing, and transformation of waste.

How would gold be extracted?

According to the website Talen24h, “The key point of this technique is the use of sponges made from protein fibrils derived from the cheese industry. These sponges, once immersed in the metal solutions from dissolved devices, manage to attract and retain gold ions. Finally, a heat treatment transforms these particles into small nuggets, from which up to 450 milligrams of 22-carat gold have been obtained from just 20 old motherboards”.

This process requires personnel trained in chemistry, technicians and waste management experts, and specialists in food innovation. Therefore, the advantages of this new approach are not limited to the economic and recycling aspects, but also introduce the possibility of a new specialization that could be a solution for those seeking employment in career transition.

Advantages of this new method

There are several and varied advantages that this new approach offers:

- The recovery of metals leads to less dependence on traditional mining.

- The creation of jobs increases the demand for qualified personnel in the field of recycling.

- The reduction in the amount of waste results in less pollution and reuse of materials.

- In the field of sustainable innovation, it opens new lines of research and development.

The rise in technological consumption has skyrocketed the volume of electronic waste. However, few consumers are aware of the value hidden in their old devices. This context makes ETH Zurich’s proposal not only seek an environmental solution but also an economic one. This process creates in itself a circular economy loop through which different areas are fed and driven: economic, waste recycling, demand for qualified personnel for this work, less dependence on traditional mining, and a reduction in pollution thanks to the reuse of these materials.